CNC Lathe Programming V2.0

Are you a machine shop apprentice?

an operators that wish to learn programming?

Maybe an engineer or student that wishes to be fully trained in CNC programming.

This course will teach you the skills you need to be a professional CNC Lathe programmer.

The award winning CNC Lathe programming course has been remade!

Already own the old CNC Lathe course? then you should have this one as a free upgrade. If not get in contact now

Curriculum

- Introduction

- About this course

- Important Information

- Header

- Safety line

- Cartesian coordinate system

- Centre line operations

- Boring

- Centre line drilling part 1

- Centre line drilling part 2

- Centre line tapping

- Roughing and finishing cycles

- G17, G18 and G19 working planes

- Surface cutting speed

- Roughing cycle G71

- Facing cycle G72

- Pattern cycle G73

- Finishing cycle

- Turning operations

- Screw cut part 1

- Screw cut part 2

- Parting off cycle

- Sub Spindle

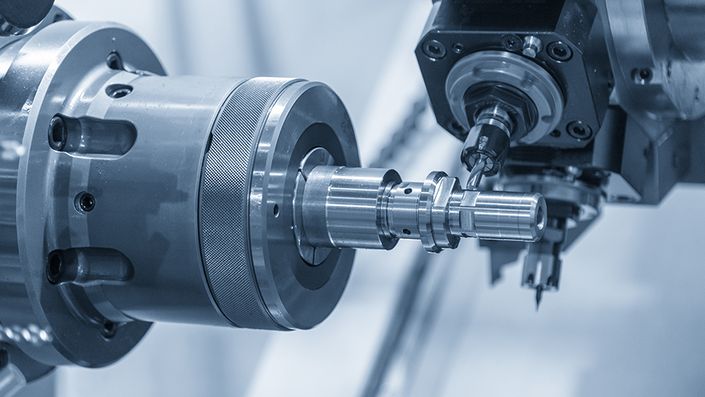

- Driven tooling

- Z Axis milling

- Y Axis milling

- Cross axis drilling

- Cross axis tapping

- Z axis drilling with driven tooling

- Z axis tapping with driven tooling

- Reference charts

- Screw thread charts

Your Instructor

My journey into the world of machining started in 1991 when I landed an apprenticeship at British Aerospace. For the first year, I studied general engineering principles where I learnt about every type of shop floor manufacture from welding, sheet metal work, bench fitting, tool making and of course machining. The following two years I specialised in manual machining, I found this to be a very important stage of my study as learning the feel of a manual machine enabled me to understand the limits of the CNC machines later in my career, and also gave me knowledge on how different materials behave under the high stress of the material removal process.

Moving on to CNC machines was a massive life-changing moment, I still remember that day clearly. Seeing the possibilities of rapid industrial manufacture blew me away and grabbed my interest like nothing else, I was hooked. The rest of my apprenticeship was spent with journeyman teaching me how to program and operate 2 axis Lathes then onto 3 axis milling machines, then 5 axis mills until eventually I was setting, programming and operating 7 Axis machining centres with dual spindles and live tooling.

Over 34 years experience

At this point in my training, I had finished the college courses I needed to be a qualified CNC Machinist. So I enrolled in night school and studied advanced CNC programming then another course on Computer Aided Design (CAD) Computer Aided Manufacture (CAM) and Computer Aided Programming (CAP) I had a thirst for learning and wasn’t about to stop there. So I enrolled in an ONC/HNC 4-year university course studying mechanical engineering.

Altogether I had spent 10 years studying engineering by the time I was 26. After working as an Aerospace CNC machine tools engineer for over 30 years for GE, Airbus, Boeing and a range of military contractors I discovered I enjoy teaching apprentices. So I am building online courses to help the new guys in the trade to excel in this exciting world of CNC Machining.